Is Your Electric Panel a Fire Risk?

Take a look at your electrical panel. If any of the labels in it say “Zinsco,” you may have a fire risk. These older electrical panels would not pass today’s UL (Underwriters Laboratories) listing and would not be sold to the general public.

Zinsco design flaws that lead to fires include:

- The connection between the breakers and the bus bar, which provides power to the circuits, is not secure.

- Certain components contain aluminum, which has a useful life of about 30 years.

- An easily corroded bus bar.

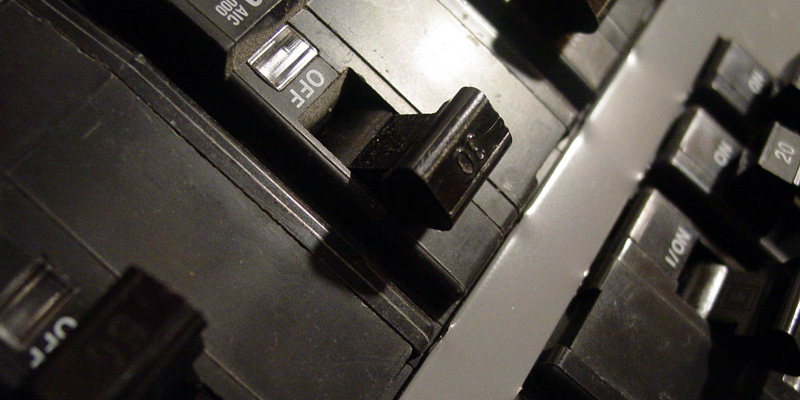

- Although the breaker appears to be off, internally, the panel may still be conducting power.

Background

Throughout the 1970s, especially in the Western United States, it was common to have a Zinsco panel installed in a new building. When Zinsco was sold to GTE Sylvania in 1973, the company continued to make panels that included Zinsco somewhere in the name. Zinsco breaker production was halted in the mid-70s.

The risk

Zinsco breakers are known to have a manufacturing defect and may be prone to higher rates of failure. While these panels may have worked fine for years, today’s modern buildings and operations have increased energy demands, which may exacerbate failure. Specifically, Zinsco breakers use an aluminum, horseshoe-shaped clip that attaches each breaker to a bus bar. The breakers are also devoid of an effective device to keep this clip firmly attached to the bus bar. Zinsco panels may use either an aluminum or a copper bus bar. Over time, the aluminum clip expands and contracts with heat and may fail to keep good contact with the bus bar resulting in “arcing”. If an aluminum bus bar is used, it may corrode causing a poor connection and arcing. The arcing then creates a “welding effect” that melts the metal and plastic construction of the individual breaker. This breaker can then melt the adjacent breaker and there can be a chain reaction where the entire panel may catch fire and/or explode sparks into the nearby environment.

Also, a breaker can melt to a panel’s bus bar and will no longer adequately trip in case of an overcurrent or short-circuit resulting in an extreme amount of power from the outside electrical supply surging into the panel and circuits. Once that happens, the power cannot be stopped or shut off manually. Electricity flow will continue until shut off at the main or the wires melt. This leads to a panel that could overheat and catch fire.

What should I do if I have a Zinsco panel?

Unfortunately, damaged or failing Zinsco breakers are not obvious by sight. You should have your panel inspected by a licensed electrical contractor. A reputable electrician should be willing to provide you with a 100% free safety analysis. Due to the inherent design flaw, all Zinsco breakers/panels should be replaced with current, UL listed equipment.

How can early detection prevent a fire?

At an assisted living facility, a Great American Loss Prevention consultant scanned a Zinsco panel using his infrared thermal camera. When a temperature reading is more than 20 degrees above ambient, we recommend a licensed electrician inspect the panel. In this case, the electrician recommended that the facility replace the panel.

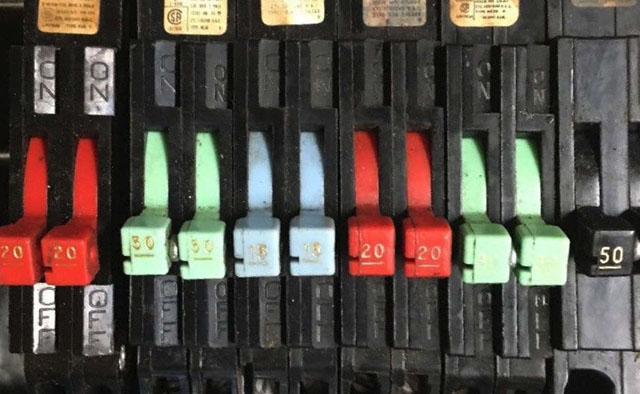

How can a Zinsco Panel be identified?

In your electrical panel box, look for any panel labels that say:

- Zinsco

- Sylvania

- Sylvania-Zinsco

- GTE-Sylvania

Manufacturers or vendors of Zinsco-style circuit breakers include:

- Challenger, Challenger Electric

- Connecticut Electric, also known as Unique Breakers, Inc. or UBI

- GTE Electric

- Kearney Electric

- Millbank Electric

- Thomas & Betts Electric

Inside the panel box individual breakers often have bright blue, red, and green tabs. However, do not assume that black breakers are not Zinsco as these were used as well.